Delivering Next-Generation Millimeter Wave Imaging for Supply Chain Applications

Delivering Next-Generation Millimeter Wave Imaging to See Through Boxes for Supply Chain Applications

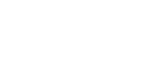

Today’s fast-moving supply chains require actionable insights to keep them moving at top speed and maximum efficiency. At the package level, visibility is key. ThruWave’s technology enables a completely different class of visualization beyond what is possible from cameras alone: Our sensors can see inside of sealed packaging, enabling you to automatically verify Delivering Next-Generation Millimeter Wave Imaging for Supply Chain Applications

Three Supply Chain challenges

1. Incoming shipment verification

With today’s just-in-time manufacturing flows, errors in supplier shipments can have devastating effects. According a study conducted by Nielsen Research and commissioned by ATS, “While one minute of stopped (automobile) production, or downtime, costs an average of $22,000, some survey respondents cite the figure to be as high as $50,000 per minute.”

2. Inventory verification

ABI Research1 has reported that using traditional inventory counting methods yield inventory accuracies of around 65%, leading to frequent stock-outs.

A CNBC report estimates the total value of lost sales for retail businesses due to stock-out issues was $634.1 billion in 2015.

3. Return fraud prevention

According to NRF’s 2015 retail return fraud survey, almost 4 percent of total returns are fraudulent. Annual merchandise return fraud and

abuse combined is estimated to be between $9.1 billion and $15.9 billion for the entire retail industry.

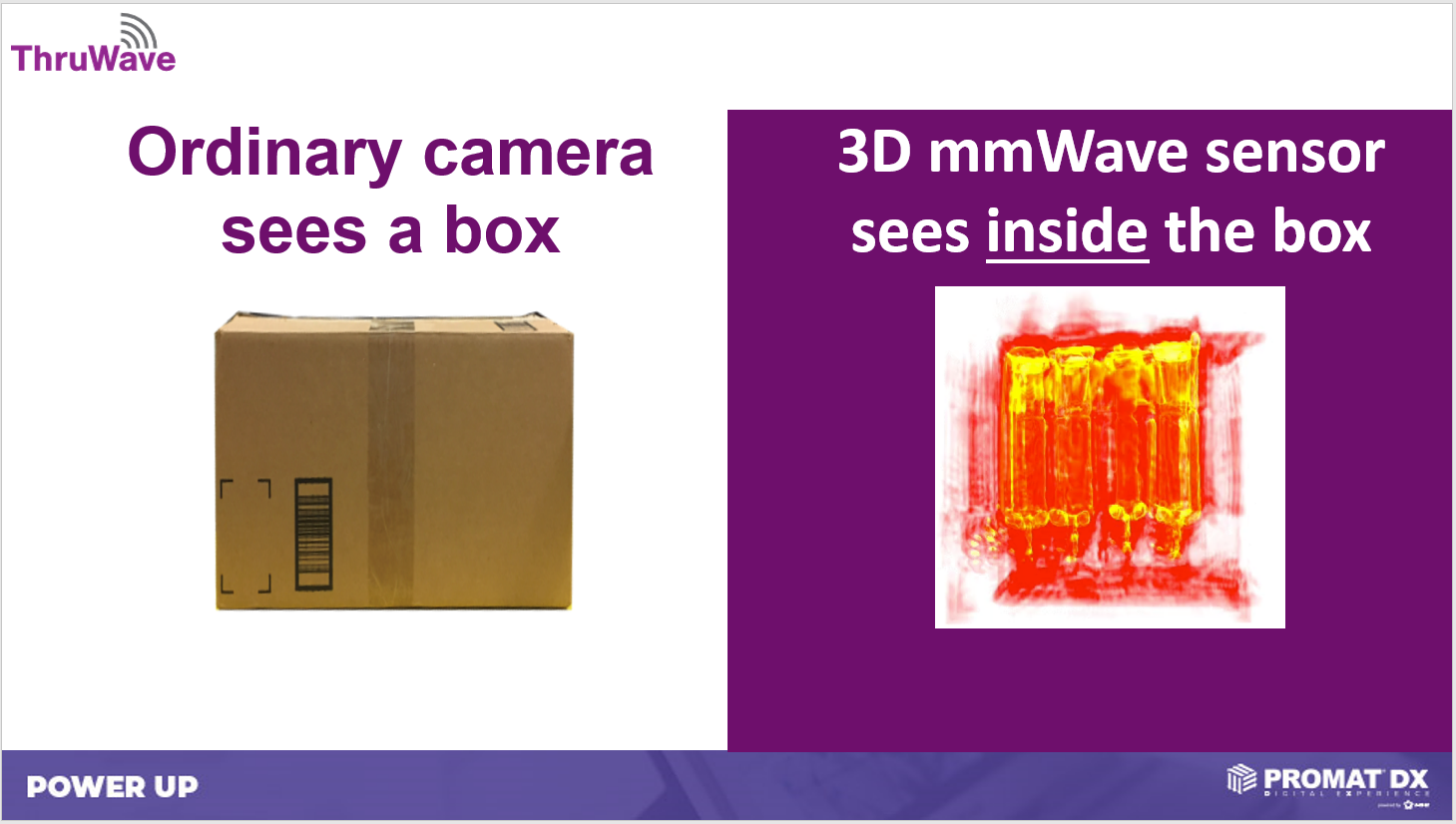

Quality Control Reimagined

ThruWave’s mmWave sensors see through packaging materials to make 3D images of both package and contents at conveyor speeds. ThruWave 3D datasets are similar to a CT scan, but are human safe without the health hazard of an X-ray system and with more compact equipment at lower cost. ThruWave's unique 3D millimeter wave imaging solution is automated and can reduce the need for manual human inspection labor.

1. Count number of items inside packaging

Serialization of products like pharmaceuticals requires verification of the number of items packed. Scanning packed items at end of line inspection stations ensures that the correct number of items are shipped in each package.

2. Verify incoming inventory

Using the sensor in conjunction with a bar code scanner to retrieve the shipping manifest, shipments of packaged goods can be verified prior to being placed into inventory without having to open the packaging.

3. Detect missing items

Errors in the packing process can result in shipments with missing items. Early detection by scanning after goods have been packaged can minimize disruption and loss further down the chain. Also, attempted fraud can be efficiently detected by scanning packages without the

additional cost of opening them.

4. Detect damaged items

Delivering damaged items to customers is highly undesirable and can hurt shippers’ reputations. Scanning items prior to delivery can prevent broken items from being delivered and identify where in the chain of custody the damage occurred.

5. Exterior dimensioning

When shipping in space-limited trucks or containers, measuring proper exterior dimensions is critical. The sensor can measure these dimensions to sub-centimeter accuracy.

6. Automatic inventory verification

Manually picked warehouse shipments can yield mismatches between logged and actual count, and scanning these boxes can identify anomalies. Similarly, in a retail environment as shoppers remove items and associates replace them on the shelves, errors can accrue leading to stock-outs. Scanning through the first layer of product on shelves gives visibility into the real item counts.

How can ThruWave 3D mmWave imaging help your company?

At ThruWave, we are creating 3D millimeter wave imaging applications and solutions for various industries. If you have a problem to solve where where our technology to see through boxes and inspect contents can help, let us know. Learn more about applications for millimeter wave imaging here or about our scalable mmWave imaging solution here.

Get in touch with us email sales@thruwave.com to learn more about how we make the invisible visible and the benefits to your operation.

Recent ThruWave News and Resources