Damage Detection - Small Appliances

eCommerce, Retail

3D mmWave Imaging inspects inside closed boxes for damaged appliances

CUSTOMER STORY

DETECT DAMAGE ON RECEIVED SHIPMENTS OF SMALL APPLIANCES

A major eCommerce retailer needed to identify damaged small appliances before they are put into inventory.

CHALLENGE

Inspect 100% of received small appliances in real time vs random sampling

To maximize Quality Control (QC) coverage on small appliances, the company needed an inspection solution that could see through closed boxes to detect damaged appliances in real-time. The existing approach requires 10% - 25% of all incoming goods to be inspected which can take up to 5 minutes per item inspected.

High-value appliances can easily be damaged as they are transferred multiple times in the supply chain. Because appliances typically contain metal and glass they are prone to denting and breakage. If left undetected, the damaged products will waste space in storage and if delivered to customers result in a negative customer experience.

THRUWAVE SOLUTION

Automated, real-time inspection through closed packages

A ThruWave mmWave anomaly detection solution was installed over existing conveyor immediately after an unloader at the receiving dock to scan inbound inventory. The system included a barcode scanner for easy verification against receiving documentation and/or warehouse management records.

Instead of random sampling, the warehouse QC team used the human-safe millimeter wave solution to inspect 100% of all inbound packages of high-value items and compared them to known good images. Items with identified anomalies were flagged for disposition.

RESULTS

mmWave inspection enables detection without opening boxes

ThruWave’s mmWave imaging solution proved to be effective at scanning 100% of received goods and generating mmWave images for comparison to detect anomalies. This allows customers to:

- Improve productivity with focused QC operations

- Reduce damaged inventory being stored on racks/shelves

- Increase cycle time to return/replace damaged goods

- Improve customer satisfaction

"It would be convenient to attribute dents, rips, and punctures to the products themselves, the inconvenient truth is the supply chain is an imperfect mover. Touch points can become flash points for product damage."

- Packaging Digest

November 2019

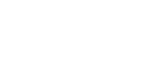

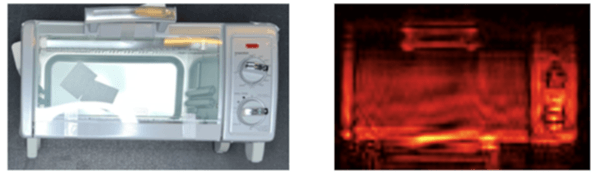

Images below are camera photos of product exterior, next to a 2D slice from a mmWave image taken after the product was re-inserted into original box and packaging. ThruWave's 3D mmWave imaging is able to see through the outer box and packaging to show what is inside and show the broken glass door of the toaster oven.

How can we help you?

Let us know what challenges you want to address with 3D mmWave imaging.